We are full-service company with turnkey food machinery solutions

As your project execution expert, we provide complete oversight from concept to start-up. Internally executing all food production line project steps, from planning and engineering to fabrication and construction, our strategic EPC approach provides you with the project supply chain certainty that keeps project life cycles intact while also reducing owner’s cost.

01

Evaluation

02

Design

03

Manufacturing

04

Civil Engineering

05

Installation

06

Training

07

After-sales Support

Build lasting value in every project

Food production line project success requires an integrated approach to consider all aspects of the project lifecycle, from initial planning to construction and operation. We understand the importance of this integrated approach and have applied it successfully for over 30 years.

As a top food engineering firm, we bring extensive expertise to each project, starting with detailed design engineering and project scopes during front-end planning and continuing to project controls that span every implementation stage.

Learn more

Consultation and Definitions

With over 30 years of experience, we can identify issues and provide effective solutions in your food production lines. We can advise on a consultancy basis whether you have questions about the right solution for your problem, or simply want to better understand the options available to you.

Our consulting services ability to understand operational challenges and apply the right food plant solutions from a range of technical disciplines sets us apart from our competition.

Project Planning and Budgeting

When we begin a new design-build construction project, our team will plan out and analyze every aspect of the proposed design to make sure it will elevate your current business model and address specific concerns in the production process.

Every aspect of the planning phase is designed with your business in mind, so you can eliminate any potential bottlenecks or delays ahead of time.

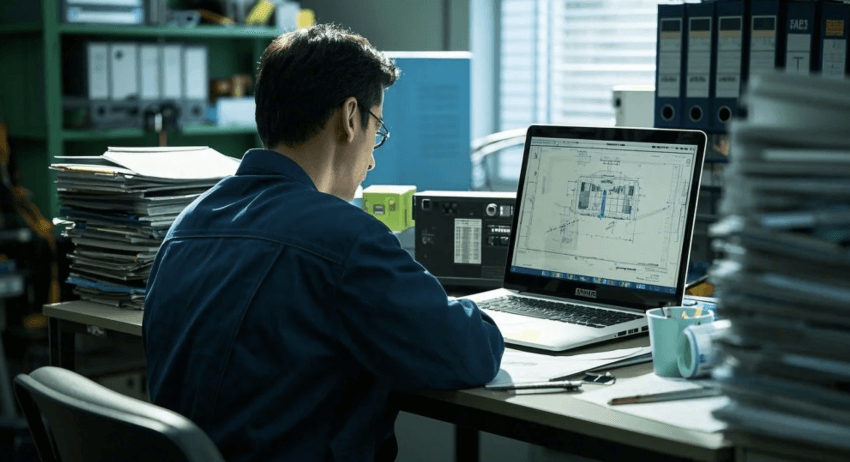

Design and Engineering

Our team at Weishine manages every aspect of the food plant build process, including the design, planning, engineering, and construction of your new system.

With expertise across the agricultural, industrial and manufacturing industries, we can create a custom solution for your facility. These systems are made with the latest technological trends and industry standards in mind, ensuring optimal efficiency at every turn.

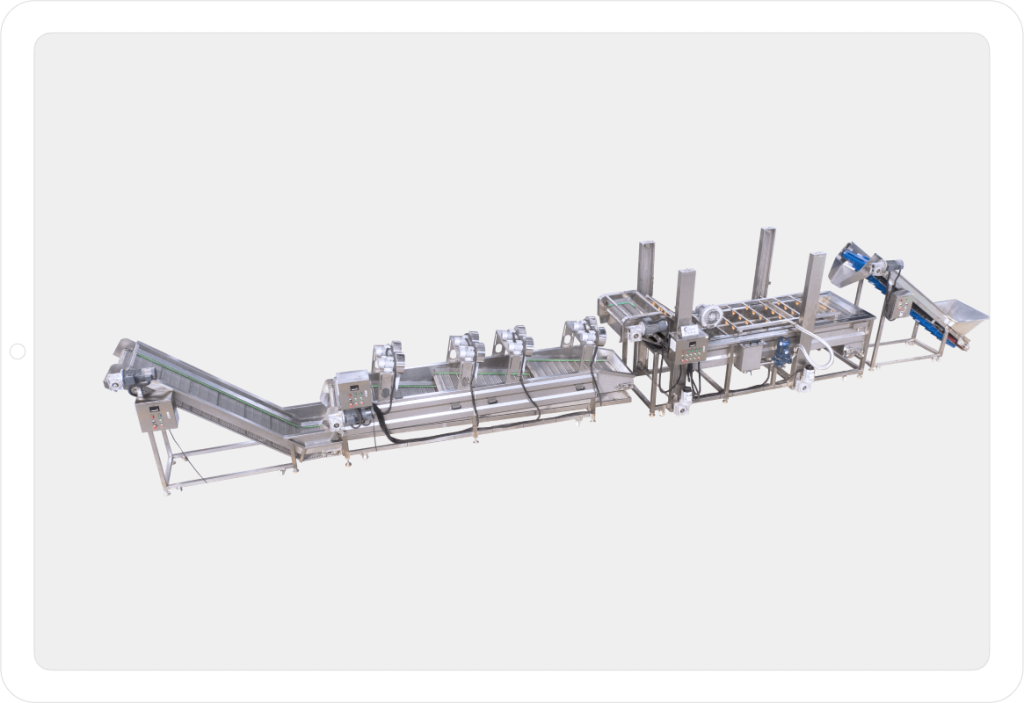

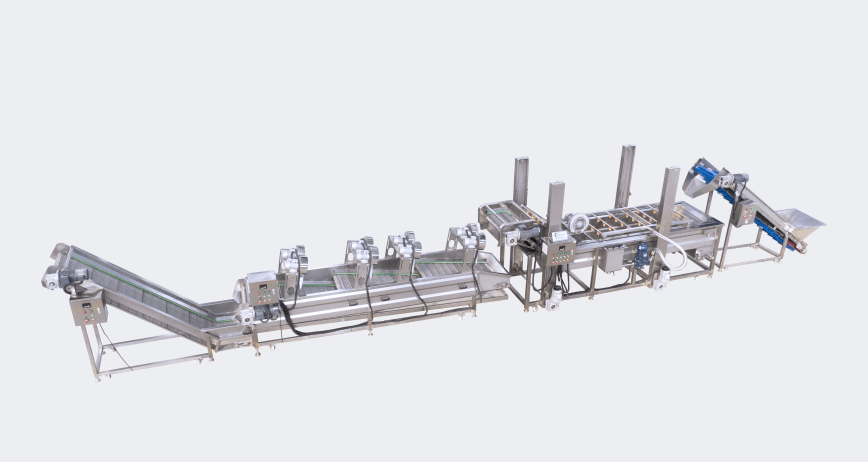

Equipment Manufacturing

Our team goes above and beyond the competition to make sure you have access to the best equipment specifications for the job at hand.

Our self-designed and manufactured products are all made to meet the regulations and quality requirements of various countries, which applies to the execution of different types of feed mills and pellet plants. These requirements ensure that that appropriate controls are in place at every stage of the manufacturing of products and systems for your business.

Equipment Testing

After the equipment is processed, in order to allow customers to fully understand the quality and operation of the new equipment, as a provider of professional granular equipment and engineering overall solutions, we can not only provide customers with testing services from a single unit to a complete system (Including all hosts and auxiliary equipment).

In addition, in the early stage of equipment procurement, we also obtain the real data of customer raw materials through quality inspection equipment (mainly for biomass raw materials), so as to have a clearer understanding of equipment effects (such as compression ratio, output, pass-through rate, etc.).

Equipment delivery

Weshine has been working hard to make every detail perfect, especially in the equipment preparation and shipment stage.

Before the equipment is packed and shipped, the order specialist will check the packing list one by one to avoid missing or under-shipping. In the equipment packing and packaging, we use professional packaging and modular solutions to ensure the safe and damage-free delivery of the equipment.

Fabrication Services

We offer comprehensive steel detailing and drafting services, encompassing detailed drawings, erection plans, shop drawings, isometric details, fabrication cut sheets, weld procedures, quality control documentation, and powder coating. Our engineering specialists utilise advanced technology to ensure product longevity, with additional services also available.

Regardless of what you’re looking to achieve, you’ve come to the right place. We specialize in construction management, maintenance, and engineering to create pellet plant facilities in the feed, biomass, organic fertilizer, and more industries that are built to last.

Equipment Installation

According to customer needs, Weshine installation engineers will guide the construction of site infrastructure, equipment installation and commissioning, and trial operation of the entire pellet production line. When the relevant project indicators meet the design standards, the customer will sign the project and pass the acceptance.

Our installers are dedicated to seamlessly delivering and setting up your machinery on site, mitigating any potential disruptions in your operations. With years of experience in the pelleting industry we are used to working in all types of spaces to ensure the successful installation of equipment tailored to your specific needs.

Facility Expansion and Renovation

The relationships developed are those of mutual respect and admiration. Like new construction jobs, we design and implement a plan based upon budget, time, space, and specifications. Unlike new construction, our familiarity with the job site is second nature and the customer feels like family.

When working on a facility expansion and/or renovation for a new customer, we take the time to understand the facility as if it was our own. We familiarize ourselves with the production load, layout of the structure, and equipment needed to complete the job.

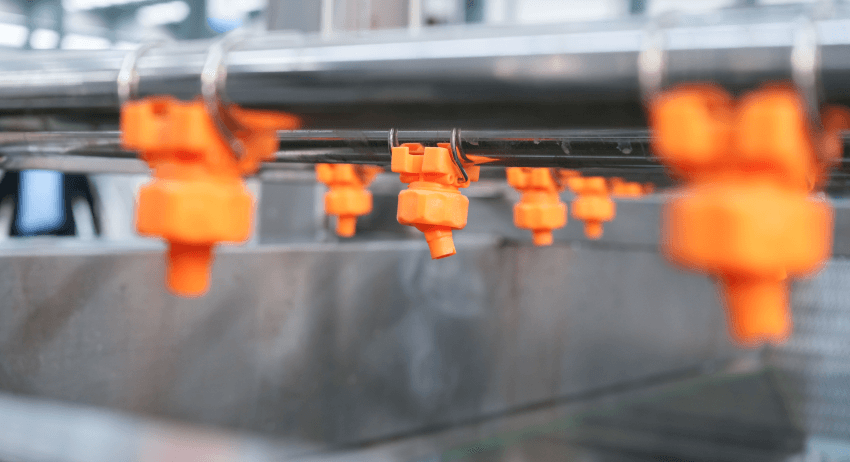

PARTS available

With Weshine equipment, you’re getting more than a machine. You’re investing in quality parts and service. That’s the part that matters. Weshine manufactures almost all parts and tooling used within their equipment. That means every component serves a unique purpose within your machine’s unique engineered design. Trust Weshine components to optimize the performance of your machine.

Weshine parts are made from high-quality materials using rigorously-tested manufacturing techniques. Parts are designed based on customer feedback. We consistently work to improve designs to help maximize part life.

Weshine, At Your Service.

Humble and wholehearted. This is who we are and why we are different. We are here for you – across the entire life cycle, whether hardware or software. We provide you timely, flexible and convenient services and support . Thanks to our global service network, there is no need to worry about shortages of machines and spare parts.

01

Advanced Technologies

Weshine invests into processing equipment, high tech process technology, hardware, software, and training yearly to keep our competitive edge on advanced pellet plant solutions.

02

Exceptional Quality

Weshine has provided quality industrial engineering solutions and engineering services for the manufacturing and distribution markets for over 30 years and pride ourselves on the ability to meet and exceed our clients ‘ goals.

03

Project Diversity and Experience

We’ve completed projects for 2000+ clients in over 60 industries across 140 + countries. Our production line projects range from $20,000 to $5 million and everything in between.

04

Boost Your Bottom Line

Value-added production line solutions that will positively affect your bottom line. Our solutions are designed to pay for themselves several times over through direct cost savings and/or cost avoidance.